NXP and ZF Friedrichshafen are collaborating on SiC-based traction inverters for EVs.

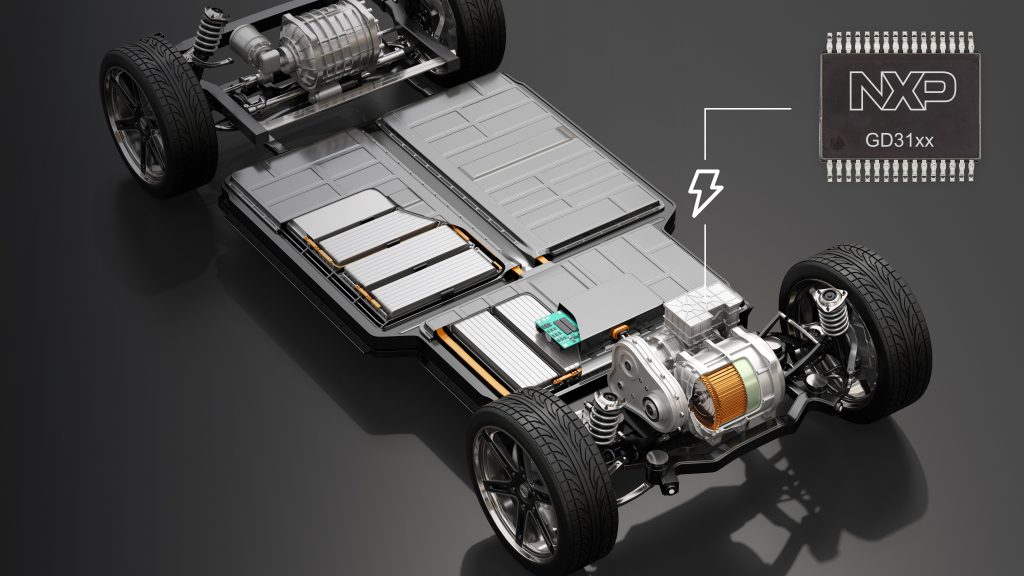

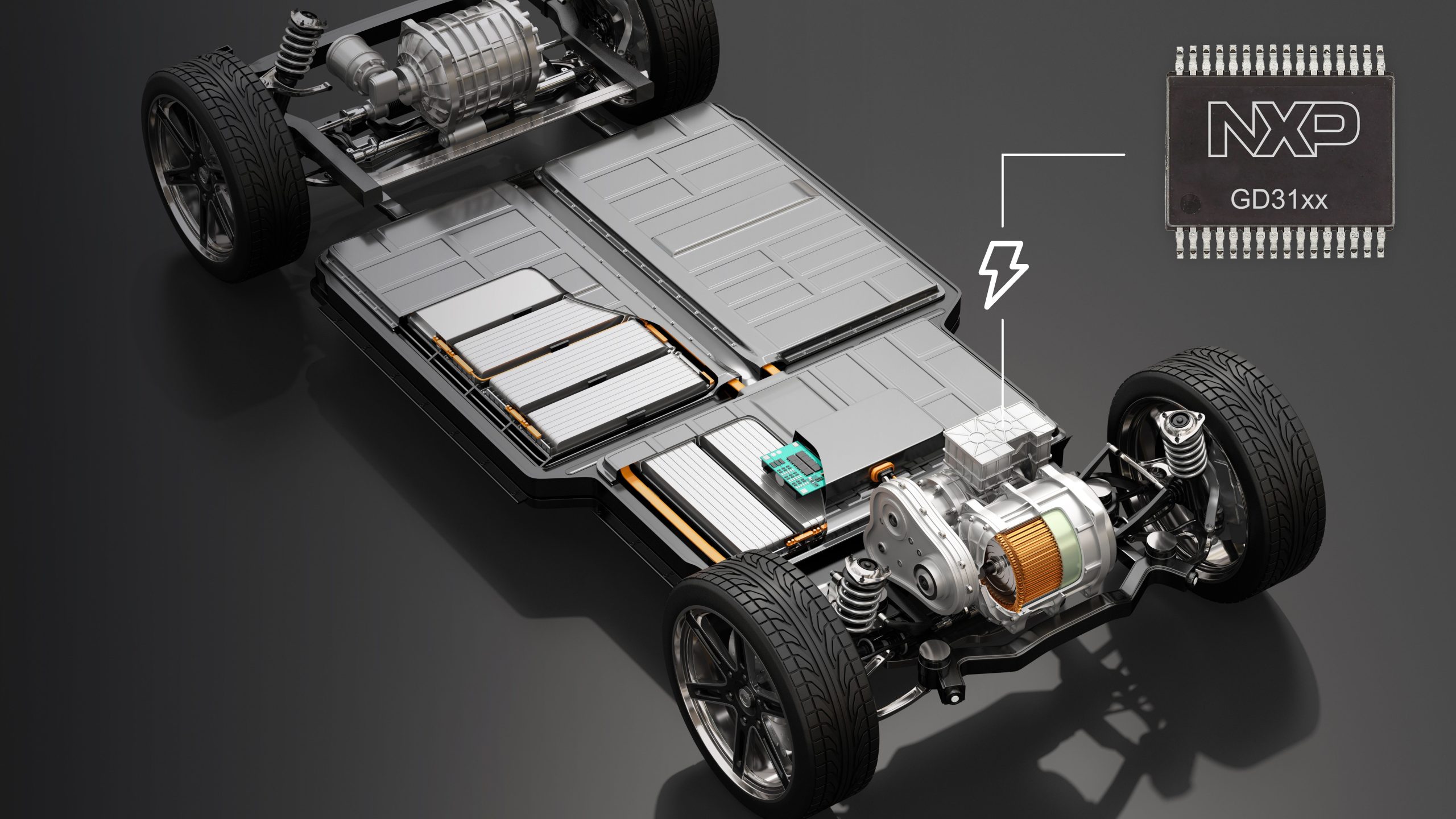

By leveraging NXP’s GD316x HV isolated gate drivers, the products are designed to accelerate the adoption of 800-V and SiC power devices.

Safe, efficient and higher performance traction inverters enabled by the GD316x product family extend EV range and reduce the number of charging stops while lowering system level costs for OEMs.

The collaboration between ZF and NXP is a significant step towards accelerating the electrification of the automotive industry, and creating more safe, sustainable, and energy-efficient EVs for the future.

“The combination of ZF’s expertise in motor control and power electronics with NXP’s GD316x gate driver family enables us to provide our latest SiC-based traction inverters with higher power and volume density, efficiency and differentiation,” says ZF svp Carsten Götte.

Traction inverters are a critical component of an EV’s electric powertrain, converting DC voltage from the battery into a time-varying AC voltage, which drives the vehicle’s motor.

As traction inverters now migrate to SiC-based designs, the SiC power devices need to be paired with HV isolated gate drivers to harness the advantages such as higher switching frequency, lower conduction losses, better thermal characteristics and higher robustness at high voltages, compared to previous generation silicon-based IGBT and MOSFET power switches.