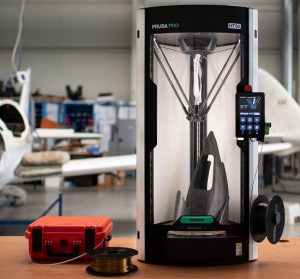

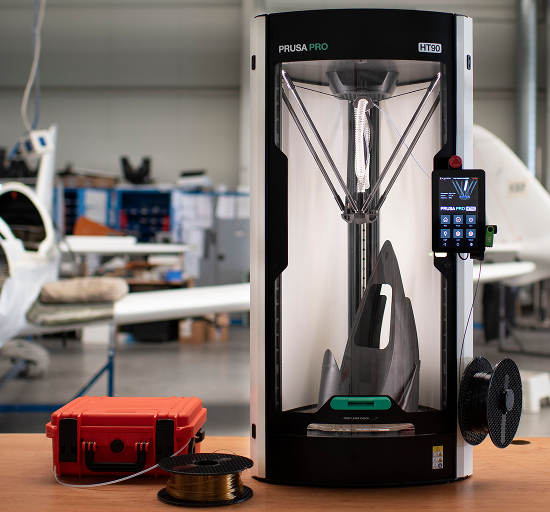

Called ‘Pro HT90’, it has a vertical cylinder build volume, 300mm in diameter and 400mm tall.

“HT90 supports a wide range of materials, from PLA to Ultem – one of the most demanding, aerospace-certified, filaments,” according to company founder Joseph Prusa. It can “excel in materials such as ASA, ABS and polycarbonate”.

“It is a high-performance material with outstanding temperature and chemical resistance, offering excellent mechanical strength. This makes it an ideal filament for demanding industries, such as aerospace and automotive,” according to Prusa.

As well as chamber heating, the HT90 has a cooling loop that injects ambient air for polymers such as PLA that need to be printed in a room temperature atmosphere. A HEPA filter is included to prevent the emission of ultra-fine particles.

It is an “all-in-one package that has all the options to follow the usual development process: start with a fast PLA prototype and proceed to the final product from a high-end polymer, with no need to switch to a different printer or wait for a supplier to ship the finished product”, said Prusa.

The 500°C head allows “PPS, PPSU, PES, PEKK, PEEK and PEI [to] be used for small-to-medium-sized objects”, said Prusa.

Although the printer can be networked and has companion print management software, for data security it can also be operated and up-dated completely off-line via USB sticks.