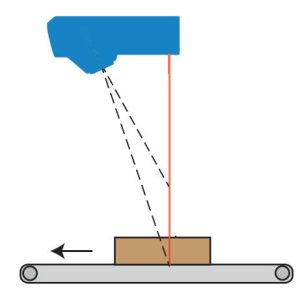

German factory automation company Sick has introduced 3d inspection cameras that can measure down to 800nm.

Called Ruler3002, 3004, 3010, the cameras work with fields of view down to 26.6mm.

“The addition of a high-powered blue [450nm] laser enables the three cameras to achieve the rapid exposure times necessary to capture the minutest three-dimensional details,” claimed the company. They “have been designed for integration into tight machine spaces with more compact dimensions than the rest of the Ruler3000 family. The Ruler3004, for example, measures 129.5 x 60.3 x 100mm”.

- 3002 has to be at least 47mm from the object and has a 9mm depth of field

- 3004 has to be at least 54mm from the object and has an 18mm depth of field

- 3010 has to be at least 99mm from the object and has a 50mm depth of field

For example, the 3010, mounted 99mm from the top of a 50mm tall object, would have a 77mm field of view at the top with 3μm z resolution, and 105mm at the base of the object with 6μm resolution. X-axis resolution varies from 32 to 45µm.

The close-in 3002 model can achieve up to 8nm in z and 11μm in x.