It uses low-latency edge computing and analytics to monitor complex semiconductor. The algorithms can provide analysis, corrective analysis and prompt actions to improve quality and yield.

Advantest said, semiconductor manufacturers can use AI algorithms and data analytics to extract insights from the “massive amounts” of data generated throughout the silicon lifecycle.

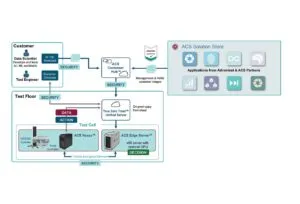

Unlike file-based analysis, online edge-computing analytics are performed in a secure, True Zero Trust environment that detects issues and applies corrective actions in milliseconds. According to Advantest, it provides real-time, adaptive decision-making with solutions that are also easy to integrate into any test programme. The communication backplane supports online edge computing/analytics for real-time adaptive decision-making within and between touchdowns.

The ACS Container Hub uses container technology to enable automated software distribution to deploy apps to the test fleet while seamlessly integrated into the ACS ecosystem.

Another feature is the ACS Edge server, a secure edge-compute and analytics solution which offers millisecond latencies.

ACS Nexus provides a standard interface for real-time test-cell data streaming and inline equipment control between equipment and external clients, enabling inline analytics capabilities and real-time control. The ACS Unified server supports scalable and redundant compute and storage resources to enhance workload management and minimise the risk of downtime while providing True Zero Trust security for the test floor. It also supports data feed forward/feedback and also provides transaction level security, cross-platform support, multi-party sharing, and data governance while enabling packet inspection and transaction logging.

ASML boosts sales despite China ban