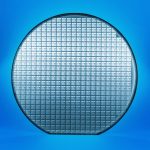

“It’s astonishing that normally, globally, people sell 12-inch silicon wafers for at least $60 to $80 each, but in China, they are offering some for $40 each and or even below $40,” a Taipei wafer distributor told the Nikkei, adding “that selling price is already lower than most global leading silicon wafer makers’ production costs of more than $50.”

The top suppliers – Shin-Etsu Chemical and Sumco of Japan, Taiwan’s GlobalWafers, Siltronic of Germany and SK Siltron of South Korea are also coming up against another challenge – Chinese electronics companies are encouraging their suppliers to use domestically produced wafers.

It is also reported that SMIC, Hua Hong, ChangXin Memory Technologies and Yangtze Memory Technologies have been asked by government agencies to use locally made wafers.

Goldman Sachs estimates that Chinese suppliers could supply around 45% of domestic demand for 300mm wafers this year, and more than 50% by 2027.

“For 8-inch wafers, self-sufficiency rates are already 80%,” says David Dai of Bernstein, In memory chipmaking cases, the percentage is even higher.”

The Chinese wafer industry has been boosted by government subsidies and has been targeted at market expansion. China’s largest wafer producer, Xi’an Eswin Material Technology, reckons it has 7% of 300mm global production capacity but has never made a profit.

In total, China now accounts for around 15% of global production capacity, reckons Dai estimated.

Next year, that could be 30%, with Eswin taking 10% global market share.