In recent years, the need for larger programme capacity and support for FOTA (Firmware Over the Air) updates has grown significantly.

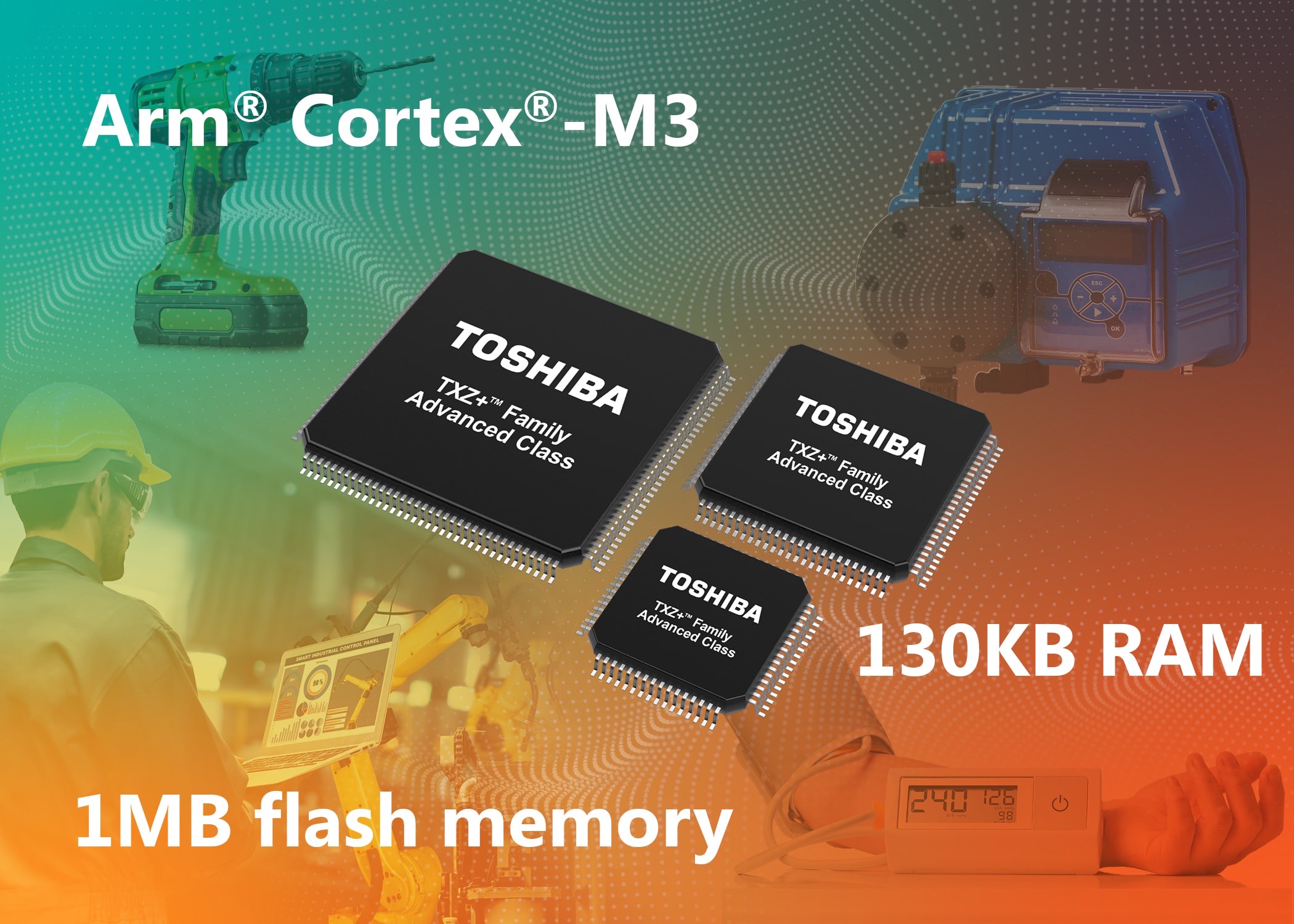

The new MCUs expand the maximum code flash memory capacity of the M3H group from the previous 512KB to 1MB and RAM capacity from 66KB to 130KB.

Within its M3H group of products, Toshiba now offers four code flash options with combinations of seven different packages.

Existing features, such as an ARM Cortex-M3 core running at speeds up to 120MHz and 32KB data flash memory with 100K program/erase cycle endurance have been maintained.

These MCUs also offer various interface and motor control options, including UART, I2C, Encoder, and Programmable Motor Driver (PMD).

The 1MB code flash memory is implemented with two separate areas of 512KB each, thereby allowing instructions to be read and executed from one area, while the updated code is programmed into the other area simultaneously.

Additionally, firmware rotation is supported by an area swap functionality – the key advancement within these new devices (along with the increased memory).

The devices include UART, I2C, TSPI, a two-unit DMAC, and an LCD controller.

The new devices support a wide variety of sensing applications with a high-speed, high-precision 12-bit analog/digital converter (ADC) that allows two types of sample and hold (S&H) times to be set for each of the 21 ADC input channels.

In addition, they are suitable for controlling AC motors and brushless DC (BLDC) motors in combination with an advanced PMD circuit that can operate synchronously with the high-speed, high-precision ADC.

The self-diagnosis functions incorporated in the devices for the flash memory, RAM, ADC and clock help customers to achieve IEC60730 Class B functional safety certification.

Alongside the MCUs, a new evaluation platform is available. Created in partnership with MikroElektronika, the CLICKER 4 for TMPM3H board, combined with the CLICKER 4 Inverter Shield, is a simple to use and cost-effective solution for experimenting with BLDC motor control scenarios.

It is supported by the MCU Motor Studio software available from the Toshiba website .

This software package features two main components: a Motor Control PC Tool that allows parameter configuration, drive control, real-time logging and diagnostics via high-speed UART as well as a scalable, fully configurable Motor Control Firmware for the M3H MCU.

Documentation, sample software with actual usage examples, and driver software that controls the interfaces for each peripheral can be downloaded from the Toshiba website:

https://toshiba.semicon-storage.com/eu/semiconductor/product/microcontrollers/software-library/txzplus-m3h-group.html

Evaluation boards and development environments are provided in cooperation with MikroElektronika and with ARM global ecosystem partners. For more information on MikroElektronika’s CLICKER 4 for TMPM3H board please visit

https://www.mikroe.com/clicker-4-for-tmpm3h.

A complete overview of devices in the TXZ+ Family Advanced Class can be accessed here:

https://toshiba.semicon-storage.com/eu/semiconductor/product/microcontrollers.html

https://toshiba.semicon-storage.com/eu/semiconductor/product/microcontrollers/txz3aplus-series.html