Figure 1: Over half of all engineers, CTOs and buyers in the electronic system design space believe their role will become more challenging during the next 12 months

This is worrying, but it is also somewhat disconnected (please excuse the pun from a connector system developer) from the industry’s current economic state. If we look at the connector market, its forecast for continual growth in the next decade and is set to reach $105.7 bn by 2034, up from $71.7 bn last year.

And this figure isn’t an outlier, if anything it’s conservative, with other analysts predicting an average growth of approximately 6% CAGR (from 3.9% to 7.4% dependent on the analyst). And this matches the electronics industry as a whole, which is again expected to see continued growth in this range.

The survey quizzed over 300 professionals developing systems for aerospace, automotive, industrial, and telecoms and beyond. What we saw in the results was that this nervousness is being caused by a range of factors: particularly cost pressures and supply-chain disruption. But there are signs of optimism.

System development advances

Industry advances are driving companies to adopt increasingly novel technologies in their system development.

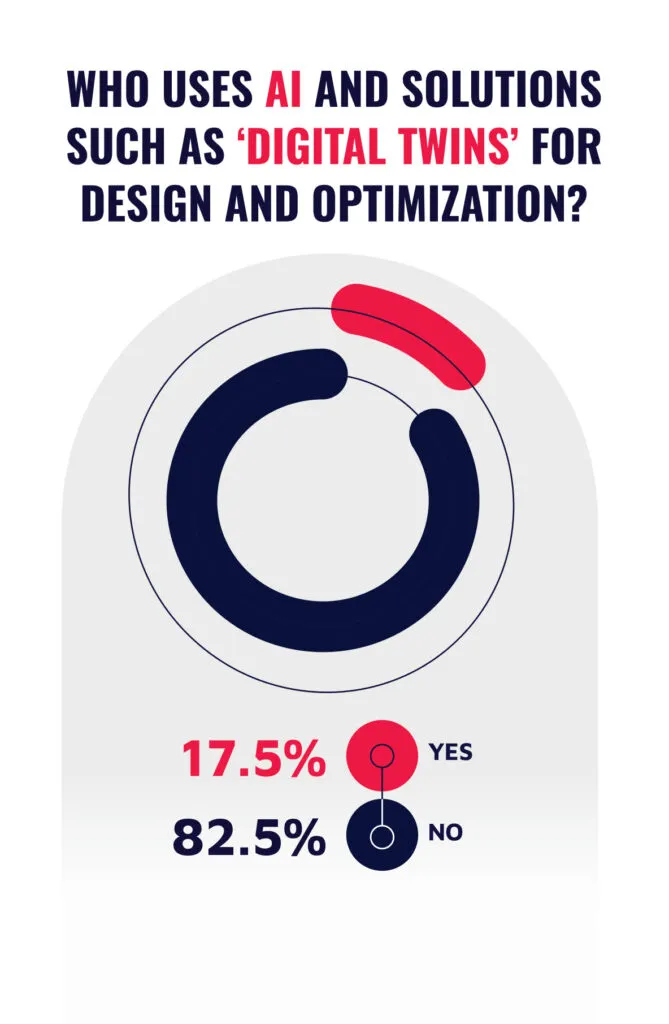

Tools such as AI and digital twins are now being used to assist in PCB design and component selection. AI is already being utilised by more than one in six of those surveyed (17.5%) and a similar number say that they expect to start doing so.

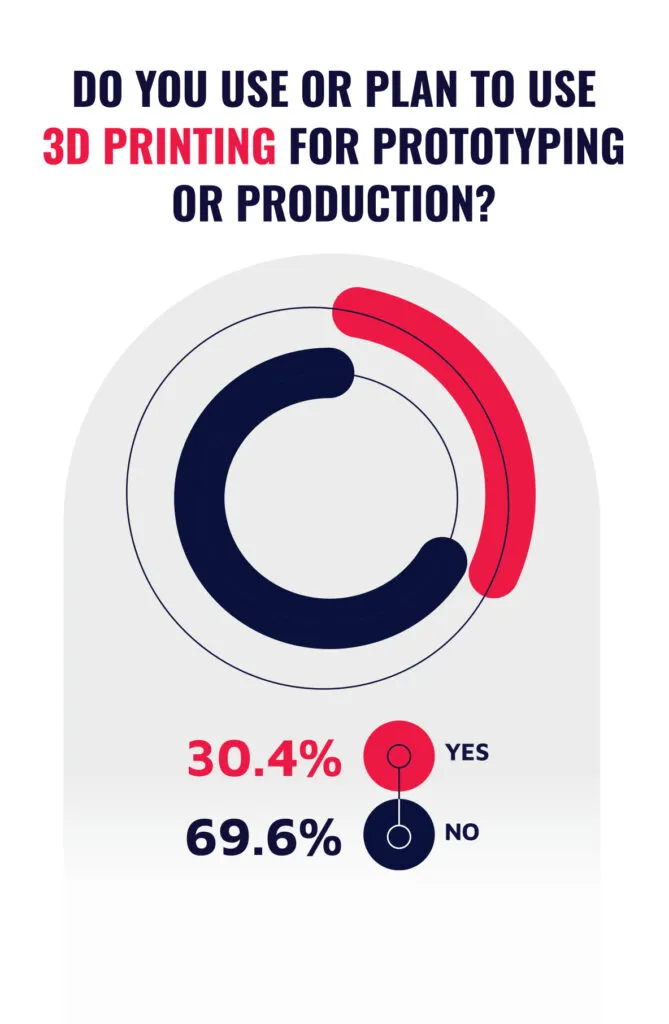

Figure 2: (a)(b) Engineers and system developers are turning to advanced tools such as AI/digital twin technologies and 3D printing to speed development and optimise supply chains.

This is important, as AI was highlighted as a tool that can not only accelerate qualification and enable the automation of testing, but also can allow for predictive maintenance during manufacturing and the optimisation of the overall supply chain.

In a similar vein, 3D printing is also proving an essential tool to those questioned, and not just in the prototyping stage, but for sampling quantities and for small-batch production too. Indeed, over 30% of respondents are already using it, be it to speed up development time or to undertake material evaluations.

Connector configuration

While connectors are essential components of nearly every electronics application they can be easily overlooked by design teams as they focus their initial prototyping efforts on the critical functionality provided by processors, controllers and other semiconductors. And being honest, for many engineers connector design and implementation is often outside (or at best adjacent) their core competence.

The connector industry is starting to address this, with Harwin launching a cable configuration tool last year. Such online tools significantly simplify the process by guiding engineers through the specification process for a cable assembly. Users select the connector series (based on material, ruggedness, reliability etc. requirements) plus pin count, and cable details, with the system validating choices in real-time to prevent incompatible combinations. 3D models for integration into CAD, and 2D technical drawings are then generated alongside all part numbers for pricing.

Some such systems also allow engineers to reverse engineer designs to generate configurations and quotes based on existing assemblies, with the digital approach eliminating manual design cycles and sourcing errors.

Conclusion

The 2025 Connector Specifier and Buyer Survey highlights that engineers are anticipating their roles will get more complex in 2026, especially in relation to increased cost pressures and supply-chain disruption.

AI, digital twins and the growth of other online tools, such as component configurators, have the ability to undo some of these headaches and allow expertise to be focused on more innovation-related design challenges instead.

With the number of engineers using such tools set to double, we’ll see if the same trepidation exists in the 2026 survey.

See Harwin.com for more information.