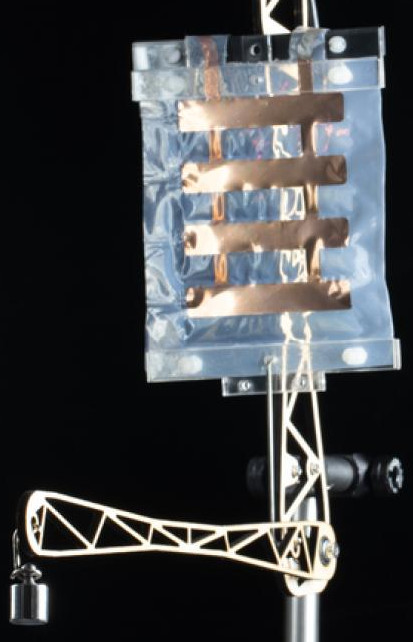

These actuators consists of a flat plastic bag of dielectric liquid with electrodes on opposite faces of the bag.

If a high potential difference is placed between the two electrodes, they are attracted together, squishing the fluid out of the way.

This action can be exploited in various mechanical arrangements to provide force, movement, or both.

From the left: relaxed, then actuated, then unwanted droop despite continued actuation

“However, until now, applying constant electrical activation only allowed short-term muscle contractions, posing a significant limitation for practical applications,” according to the Italian Sant’Anna School of Advanced Studies in Pisa.

Any force created by the applied voltage decays over minutes as charges in the liquid, usually an oil, migrate close to the inside of the plastic bag, neutralising more and more of the applied field.

There is an existing work-around for this, according to the university, which is to superimpose a high-amplitude alternating bias voltage on to the dc actuation voltage, but this needs extra power and complicates drive electronics.

Several researchers from different universities were working on other projects, and happened to test a prototype biodegradeable electrostatic soft actuator in a prototype soft actuator tester.

They discovered that the force of this actuator did not decay with time.

“As soon as we noticed that this material can sustain a constant force for arbitrarily long periods, we realised we had made a significant discovery,” said Sant’Anna research engineer Ion-Dan Sîrbu.

This sparked a theoretical study that uncovered the mechanisms involved, and provided a way to design non-drooping actuators from scratch.

“The beauty of our model is its simplicity – it can be explained with high school physics knowledge and is not limited to existing actuators,” said Johannes Kepler University physicist David Preninger. “We believe our results provide the scientific community with a simple tool for designing and investigating new systems.”

Given the permittivity and conductivity of both the enclosing polymer film and the liquid inside, they found that this formula ensures a non-droop actuator:

(film conductivity) x (liquid permittivity) = (liquid conductivity) x (film permittivity)

The problem with earlier actuators was that the enclosing plastic was such a good insulator that its tiny conductivity skewed the balance of the formula.

If a somewhat electrically leaky polymer is used, such as the biodegradeable plastic, then charges in the liquid can harmlessly bleed away, instead of accumulating close to the plastic and negating the drive field.

The necessary leakage does result in the actuator having a static power consumption, but this is up to 1,000x less than is required by the alternating bias field technique, according to the researchers.

The team went on to developed various artificial muscles, variable gradient optics and a tactile displays using theoretically-derived material combinations.

These novel actuators, and the full theoretical framework, are described in the paper ‘Electrostatic actuators with constant force at low power loss using matched dielectrics‘, published in Nature Electronics (abstract only available without payment).

Sant’Anna and Johannes Kepler (Linz Austria) universities worked with the University of Trento.