Diraq’s qubits can be manufactured reliably with the tools of the silicon microchip trade, confirming the potential of imec’s industrial manufacturing techniques for developing large-scale silicon-based quantum computers.

Leveraging nearly a decade of careful optimisation and engineering of spin-qubit fabrication at imec, Diraq-designed devices were shown to consistently achieve over 99% fidelity in operations involving two quantum bits (or ‘qubits’).

This feat, made possible by imec’s spin qubit technology platform, is a crucial step in Diraq’s roadmap toward utility scale — the point at which a quantum computer’s value exceeds its cost.

“Achieving utility scale in quantum computing hinges on finding a commercially viable way of producing high-fidelity qubits at scale. Diraq’s collaboration with imec makes it clear that silicon-based quantum computers can be built by leveraging the mature semiconductor industry, which opens a cost-effective pathway to chips containing millions of qubits while still maximising fidelity,” says Diraq founder and CEO Andrew Dzurak.

The fidelity of a quantum operation quantifies how close the actual operation is to its ideal version and is a key metric for enabling large-scale quantum computers.

Ideally, fidelities must (far) exceed 99% across all operations. Only then are errors rare enough for quantum error correction methods to work successfully. In this work, fidelities were reproducibly measured for a set of silicon quantum dot spin qubit operations across multiple devices state preparation and measurement of the qubits (SPAM), and one- and two-qubit gate operations performed on the qubits to control their state and entangle them — the elementary operations required for a utility-scale quantum computer.

Fidelities above 99.9% were achieved for SPAM operations, and fidelities systematically exceeding 99% were shown for one- and two-qubit gate operations, making quantum error correction of industrially fabricated quantum dot qubit devices now a realistic prospect.

Typically, quantum devices fabricated in academic clean rooms are selected for measurement on the basis of their quality, a process that produces ‘hero’ devices, obscuring the reproducibility of the results.

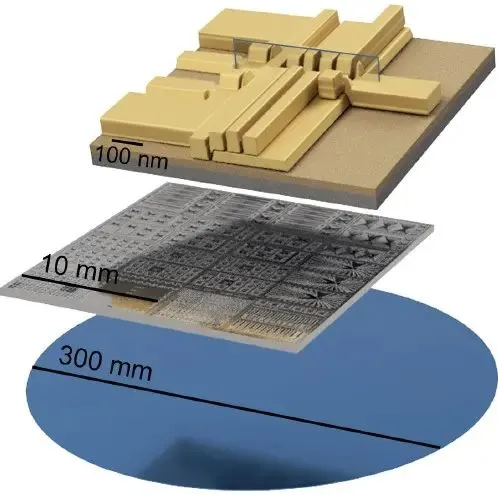

Diraq measured devices that were selected at random, obtaining reproducible data on sets of two-qubit devices, each consisting of a double quantum-dot structure. The devices were fabricated using imec’s 300mm spin qubit platform for silicon quantum-dot structures, which is optimized for low electrical noise and high uniformity. In order to also suppress the magnetic noise from residual nuclear spins in the substrate, the quantum-dot structures were fabricated on an isotopically enriched 28Si layer.

“For the first time, silicon MOS based quantum-dot spin-qubit devices realized with industrial manufacturing techniques perform as well as academic hero devices. This shows that imec’s 300mm process flow for MOS based quantum-dot structures enables a low-noise qubit environment, resulting in high fidelity values for a set of critical qubit operations.,” says imec fellow Kristiaan De Greve.