One such collaboration with ASMPT, a global leader in semiconductor packaging and electronic equipment manufacturing, highlights the unique advantages of INTAMSYS’ 3D printing solutions.

Leveraging INTAMSYS’ 3D Printing Technology to Maintain Industry Leadership

INTAMSYS and ASMPT have worked together since 2018, exploring best practices for integrating 3D printing into high-end manufacturing. As an industry leader, ASMPT has prioritized the adoption of 3D printing for its potential to streamline processes and reduce costs.

In a market crowded with emerging brands, INTAMSYS stood out for its value, offering flexibility with open-source materials and parameters – a crucial feature for early adopters needing adaptability in performance optimization and new material development.

In 2024, INTAMSYS launched the FUNMAT PRO 310 NEO, a high-speed industrial 3D printer designed for versatility. With its robust capabilities, the 310 NEO was a natural choice for ASMPT, which became one of its first users. Following extensive use, the 310 NEO demonstrated exceptional results in semiconductor equipment manufacturing, reinforcing INTAMSYS’ reputation for cost efficiency, advanced printing capabilities, material compatibility, and comprehensive support.

Key Applications of INTAMSYS’ 3D Printing Technology in Production

ASMPT has leveraged the FUNMAT PRO 310 NEO in four primary application areas:

- Prototyping: 3D printing ability to create rapid prototypes supports fast design iterations and product validation. The 310 NEO, with its ability to quickly and accurately print PC and ABS parts at 500–1000g per day, allows ASMPT engineers to bring designs to life efficiently, accelerating the R&D process.

- Tooling & Fixtures: With ASMPT’s diverse product line and intricate wiring, custom fixtures are essential for organized assembly. Although quantities are low, the fixtures require high durability. The 310 NEO efficiently produces high-strength, heat-resistant materials like PPS-CF and PPA-CF, meeting these demands with ease.

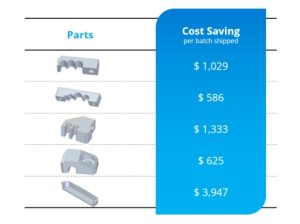

- End-Use Parts: Improvements in 3D printing materials have made it possible to manufacture end-use parts. ASMPT has used the 310 NEO to produce durable parts like protective covers, wire clips, base connectors, and TPU parts that are integrated into their products and delivered directly to customers.

- Casting & Mold Production: The 310 NEO enables cost-effective sand casting by producing large-scale models with low infill, streamlining the molding process. ASMPT found that even with a 9% infill, the printed models meet casting requirements, leading to faster, more efficient production at reduced costs

Reliability and Efficiency Driving ROI

INTAMSYS’ 3D printing equipment has earned the trust of clients like ASMPT for its efficiency, stability, and reliability. In use, the 310 NEO has reduced production times compared to traditional methods and cut production costs by 50% or more. Beyond time and cost savings, INTAMSYS’ all-inclusive support ensures seamless operations, helping clients realize fast returns on their investment.

For ASMPT, consistency, stability, and high success rates in 3D printing are essential, and these qualities have made INTAMSYS a trusted choice over the years.

The FUNMAT PRO 310 NEO combines optimized hardware, a precise print process, and a stable high-temperature chamber to achieve consistent, full-size prints. Validated by over 240,000 hours of operation and the production of 30,000 parts, the 310 NEO supports reliable, continuous production. This desktop machine bridges industrial performance with the convenience of desktop size, complementing existing large-format, high-speed industrial FFF solutions.

Introducing the FUNMAT PRO 310 NEO has significantly boosted ASMPT’s productivity – not only by reducing cost and shortening lead times but also by delivering lasting economic benefits and accelerating time to market.

For high-end manufacturers facing pressure to increase efficiency and reduce costs, collaboration with leaders in 3D printing can offer a competitive edge. INTAMSYS remains committed to innovation, advancing 3D printing technology to deliver reliable, efficient solutions across diverse industries.

About INTAMSYS

INTAMSYS is a global leader in industrial 3D printing, offering comprehensive additive manufacturing solutions and services. Established in 2016 by a team of experienced engineers, INTAMSYS has earned the trust of customers across various industries. The company specializes in FFF technology, delivering state-of-the-art FUNMA 3D printers that can handle a wide range of engineering materials, alongside its own line of high-performance materials. With offices in Germany, the United States, and China, INTAMSYS boasts a global network of partners, ensuring seamless service delivery worldwide.

For more information about INTAMSYS, please visit www.intamsys.com