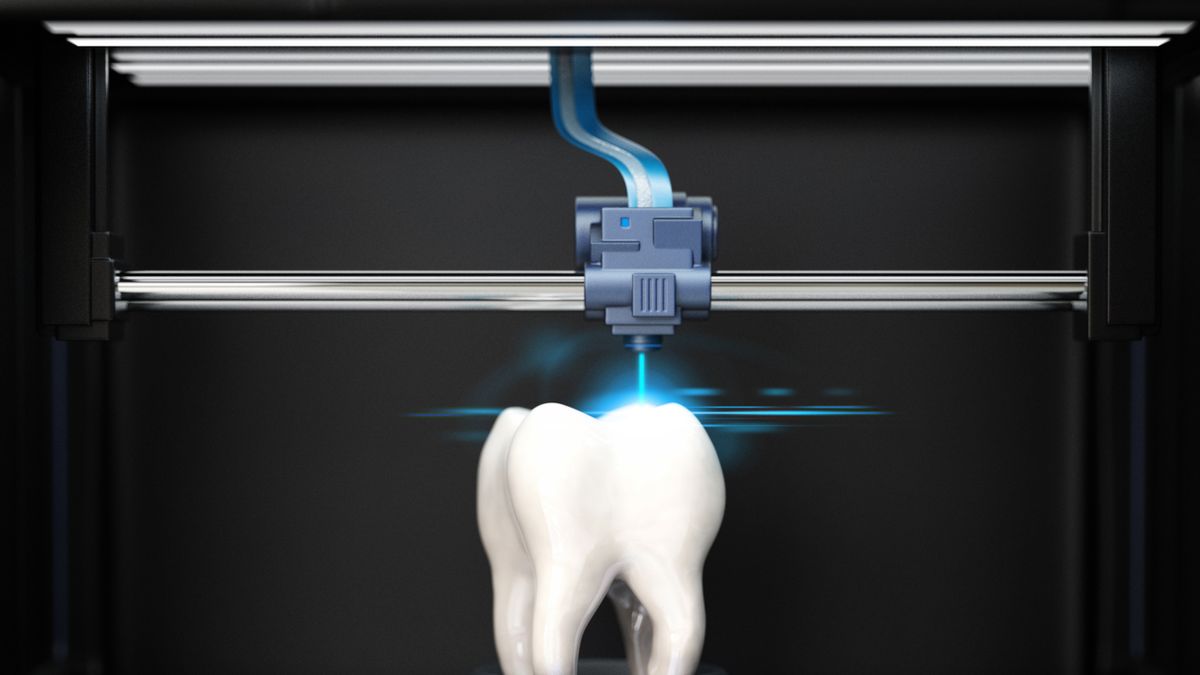

The core of SLA printing involves a laser beam precisely directed by a light-emitting device to cure the polymer resin in a resin tank. The SLA printing process goes something like this:

- You create a 3D model of your object in a CAD program.

- A piece of software chops your CAD model up into thin layers — typically five to 10 layers per millimeter.

- The 3D printer‘s laser “paints” one of the layers, exposing the liquid plastic in the tank and hardening it.

- The platform drops down into the tank a fraction of a millimeter and the ultraviolet laser paints the next layer of uncured resin to cover the previous layer.

- This process repeats, layer by layer, until your model is complete.

This is not a particularly quick process. Depending on the size and number of objects being created, the laser might take a minute or two for each layer. A typical run might take 6 to 12 hours. Runs over several days are possible for large objects (maximum size for the relatively old machine shown above is an object 10 inches, or 25 centimeters, in three dimensions).

You start by creating a 3D design for your object in a CAD program. This design is tweaked before building with supports that raise it up off the tray slightly and with any internal bracing that is required during building. The SLA then renders the object automatically (and unattended).

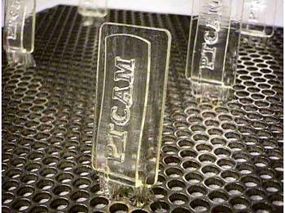

When the process is complete, the SLA raises the platform and you end up with your 3D object. If the object is small, you can produce several of them simultaneously if you like. They all sit next to each other on the tray.

The following photo shows a tray after building is complete, with several identical objects produced simultaneously:

Once the run is complete, you rinse the objects with a solvent and then “bake” them in an ultraviolet oven that thoroughly cures the plastic.

Advantages of Using SLA Technology

SLA technology offers several benefits over traditional manufacturing methods like injection molding and fused deposition modeling. It is capable of producing parts with smooth surface finishes, fine features, and high complexity without the need for multiple tools or molds.