In today’s evolving business landscape, companies must adapt their customer interactions and services to unlock new revenue and value-producing opportunities. The key lies in digitalization, which enables both operational and business model innovations. By increasing operational efficiency and embracing new ways of delivering value, businesses can gain a competitive edge.

IT/OT convergence is essential for businesses to succeed in the digital era. By merging information technology (IT) and operational technology (OT) systems, businesses can leverage scattered data to maximize their technological capabilities and transform their operations.

However, the journey towards a unified network comes with complexity. To increase efficiency, reliability, and simplify maintenance, businesses must consolidate various industrial Ethernet protocols and prepare for future network needs. While this transformation requires time and resources, prioritizing incremental improvements that are future-ready can meet immediate needs.

In this article, we provide practical advice on streamlining industrial communication networks while futureproofing your investments.

Futureproof Networking for Increased Data Connectivity

The rise of IT/OT converged applications brings a flood of data that needs to be transmitted and exchanged within industrial networks. One example is the adoption of high-resolution IP cameras for AI-based machine vision, improving quality inspection and worker safety. However, these applications require more networking devices, leading to crowded control cabinets and increased engineering efforts.

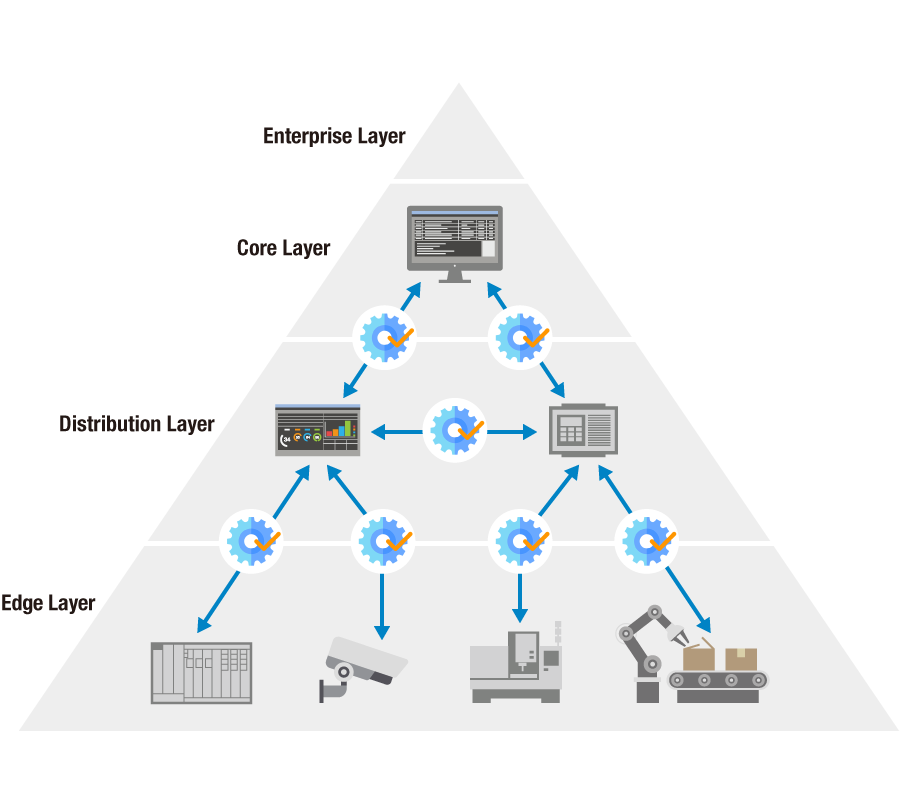

To ensure smooth communication in converged networks, businesses must anticipate future operational requirements. We recommend selecting compact solutions that fit easily into control cabinets, with modular flexibility to accommodate growing needs. Supporting multiple industrial protocols at the edge layer enables seamless interoperability and integration with SCADA/HMI systems, enhancing operational performance.

Streamlining edge-to-core data connectivity also relies on bandwidth and performance at the distribution and core layers. With Moxa’s reliable network foundation, you can create futureproof networks that seamlessly transmit data from edge to core.

Layered Protection for Enhanced Network Security

The convergence of IT and OT networks, alongside the rapid adoption of IIoT technology, has increased the overall attack surface and introduced new attack vectors. The exponential rise in cybersecurity risks poses a threat to industrial control systems (ICS) and critical infrastructures.

Historically, OT devices were physically separated, but IT/OT convergence has dissolved the air gap, exposing OT infrastructure to potential cyberthreats. Managing existing vulnerabilities within once-isolated OT networks, combined with IT-based threats, presents a complex challenge for administrators.

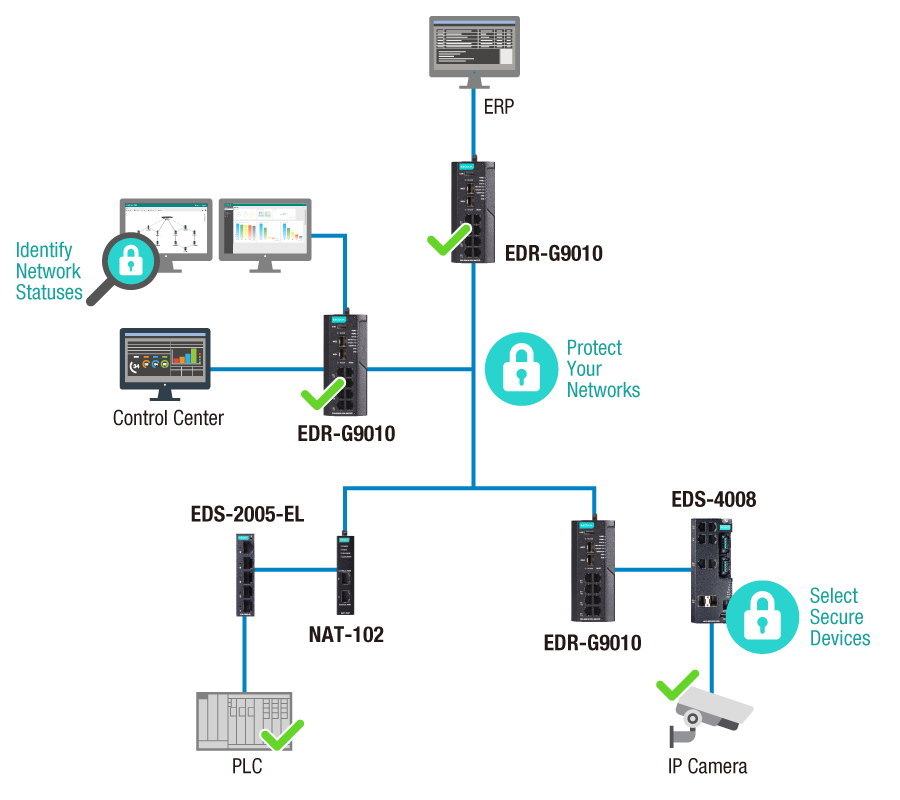

While network security is crucial, ensuring uninterrupted industrial operations is equally important. To achieve a robust network foundation, secure networking with defense-in-depth protection is key. Start by selecting security-hardened devices that comply with industrial security standards, such as IEC 62443 and NERC CIP. Then, implement essential network segmentation and proactive threat prevention measures to guard against attacks. Lastly, maintaining visibility to monitor the network’s security status is vital for timely detection and response.

Moxa provides holistic network security with three layers of defense-in-depth protection tailored to the specific needs of industrial networks. By prioritizing network protection and availability, businesses can confidently transition to a converged infrastructure while safeguarding operations.

Simplified Network Management for Seamless Operations

As IT and OT networks converge, network complexity grows, emphasizing the need for efficient network management. A single point of failure can disrupt the entire infrastructure, leading to costly downtime. Service providers require an effective network management tool that allows them to enhance network performance and availability, quickly detect and respond to problems, and seamlessly implement future expansions.

Key capabilities of an ideal OT network management tool include:

- Network visibility: Gain insights into performance, traffic load, and security status of network devices.

- Quick diagnostics: Detect and pinpoint root causes of issues swiftly, minimizing business impact. Customized event notifications enable proactive issue resolution.

- Easy maintenance: Remotely back up, restore device configurations, and upgrade firmware from a centralized location, eliminating the need for on-site visits.

Moxa offers OT-centric network management solutions designed for OT engineers, simplifying the challenges posed by network complexity. These solutions empower companies to enhance aftermarket services and explore new business models such as machine-as-a-service.

Building a Futureproof Network Infrastructure for Digitalization

As you embark on your digitalization journey, merging your IT and OT networks, it is crucial to ensure that your network infrastructure can adapt to the evolving demands. Moxa, a trusted expert in industrial networking, is dedicated to assisting businesses in embracing the next generation of industrial networking.

By understanding the unique requirements of different applications, Moxa helps organizations create a futureproof industrial network infrastructure that paves the way for success in your digitalization journey.

Author name:

Katie Tang – Product Manager, Industrial Ethernet Infrastructure

Company contact details:

Moxa Europe GmbH, Munich, Germany

Phone: +49 89 413 25 73 0

www.moxa-europe.com

www.moxa.com