By definition, a reset domain crossing (RDC) occurs when a path’s transmitting flop has an asynchronous reset, and the receiving flop either has a different asynchronous reset than the transmitting flop or has no reset. The multitude of asynchronous reset sources found in today’s complex automotive designs means there are a large number of RDC paths, which can lead to systematic faults and hence cause data-corruption, glitches, metastability, or functional failures — along with other issues.

This issue is not covered by standard, static verification methods, such as clock domain crossing (CDC) analysis. Therefore, a proper reset domain crossing verification methodology is required to prevent errors in the reset design during the RTL verification stage.

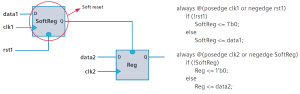

A soft reset is an internally generated reset (register/latch/black-box output is used as a reset) that allows the design engineer to reset a specific portion of the design (specific module/ subsystem) without affecting the entire system. Design engineers frequently use a soft reset mechanism to reset/restart the device without fully powering it off, as this helps to conserve power by selectively resetting specific electronic components while keeping others in an operational state. A soft reset typically involves manipulating specific registers or signals to trigger the reset process. Applying soft resets is a common technique used to quickly recover from a problem or test a specific area of the design. This can save time during simulation and verification by allowing the designer to isolate and debug specific issues without having to restart the entire simulation. Figure 1 shows a simple soft reset and its RTL to demonstrate that SoftReg is a soft reset for flop Reg.

Figure 1. SoftReg is a soft reset for register Reg.

This article presents a systematic methodology to identify RDCs, with different soft resets, that are unsafe, even though the asynchronous reset domain is the same on the transmitter and receiver ends. Also, with enough debug aids, we will identify the safe RDCs (safe from metastability only if it meets the static timing analysis), with different asynchronous reset domains, that help to avoid silicon failures and minimize false crossing results. As a part of static analysis, this systematic methodology enables designers to intelligently identify critical reset domain bugs associated with soft resets.

A Methodology to Identify Critical Reset Domain Bugs

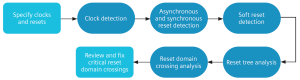

With highly complex reset architectures in automotive designs, there arises the need for a proper verification method to detect RDC issues. It is essential to detect unsafe RDCs systematically and apply appropriate synchronization techniques to tackle the issues that may arise due to delays in reset paths caused by soft resets. Thus designers can ensure proper operation of their designs and avoid the associated risks. By handling RDCs effectively, designers can mitigate potential issues and enhance the overall robustness and performance of a design. This systematic flow involves several steps to assist in RDC verification closure using standard RDC verification tools (see figure 2).

Figure 2. Flowchart of methodology for RDC verification.

Specification of clock and reset signals

Signals that are intended to generate a clock and reset pulse should be specified by the user as clock or reset signals, respectively, during the set-up step in RDC verification. By specifying signals as clocks or resets (according to their expected behavior), designers can perform design rule checking and other verification checks to ensure compliance with clock and reset related guidelines and standards as well as best practices. This helps identify potential design issues and improve the overall quality of the design by reducing noise in the results.

Clock detection

Ideally, design engineers should define the clock signals and then the verification tool should trace these clocks down to the leaf clocks. Unfortunately, with complex designs, this is not possible as the design might have black boxes that originate clocks, or it may have some combinational logic in the clock signals that do not cover all the clocks specified by the user. All the un-specified clocks need to be identified and mapped to the user-specified primary clocks. An exhaustive detection of clocks is required in RDC verification, as potential metastability may occur if resets are used in different clock domains than the sequential element itself, leading to critical bugs.

Reset detection

Ideally, design engineers should define the reset signals, but again, due to the complexity of automotive and other modern designs, it is not possible to specify all the reset signals. Therefore a specialized verification tool is required for detection of resets. All the localized, black-box, gated, and primary resets need to be identified, and based on their usage in the RTL, they should be classified as synchronous, asynchronous, or dual type and then mapped to the user-specified primary resets.

Soft reset detection

The soft resets — i.e., the internally generated resets by flops and latches — need to be systematically detected as they can cause critical metastability issues when used in different clock domains, and they require static timing analysis when used in the same clock domain. Detecting soft resets helps identify potential metastability problems and allows designers to apply proper techniques for resolving these issues.

Reset tree analysis

Analysis of reset trees helps designers identify issues early in the design process, before RDC analysis. It helps to highlight some important errors in the reset design that are not commonly caught by lint tools. These include:

- Dual synchronicity reset signals, i.e., the reset signal with a sample synchronous reset flop and a sample asynchronous reset flop

- An asynchronous set/reset signal used as a data signal can result in incorrect data sampling because the reset state cannot be controlled

Reset domain crossing analysis

This step involves analyzing a design to determine the logic across various reset domains and identify potential RDCs. The analysis should also identify common reset sequences of asynchronous and soft reset sources at the transmitter and receiver registers of the crossings to avoid detection of false crossings that might appear as potential issues due to complex combinations of reset sources. False crossings are where a transmitter register and receiver register are asserted simultaneously due to dependencies among the reset assertion sequences, and as a result, any metastability that might occur on the receiver end is mitigated.

Analyze and fix RDC issues

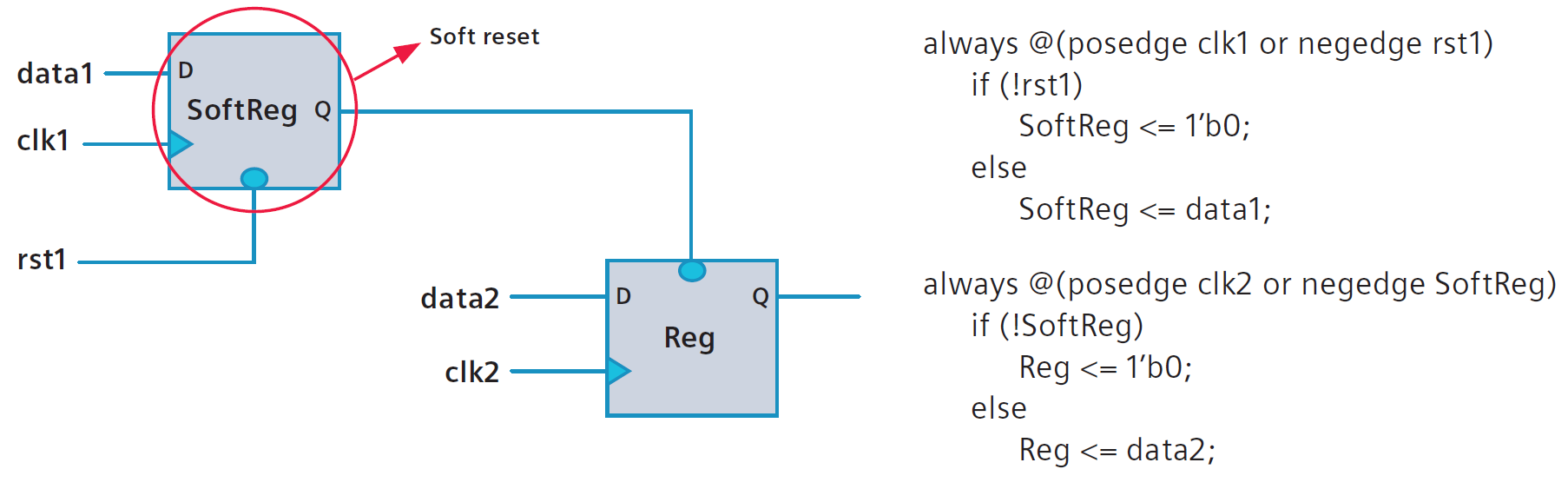

The concluding step is to analyze the results of the verification steps to verify if data paths crossing reset domains are safe from metastability. For the RDCs identified as unsafe — which may occur either due to different asynchronous reset domains at the transmitter and receiver ends or due to the soft reset being used in a different clock domain than the sequential element itself — design engineers can develop solutions to eliminate or mitigate metastability by restructuring the design, modifying reset synchronization logic, or adjusting the reset ordering. Traditionally safe RDCs — i.e., crossings where a soft reset is used in the same clock domain as the sequential element itself — need to be verified using static timing analysis.

Figure 3 presents our proposed flow for identifying and eliminating metastability issues due to soft resets. After implementing the RDC solutions, re-verify the design to ensure that the reset domain crossing issues have been effectively addressed.

Figure 3. Flowchart for proposed methodology to tackle metastability issues due to soft resets.

This methodology was used on a design with 374,546 register bits, 8 latch bits, and 45 RAMs. The Questa® RDC verification tool using this new methodology identified around 131 reset domains, which consisted of 19 asynchronous domains defined by the user, as well as 81 asynchronous reset domains inferred by the tool.

The first run analyzed data paths crossing asynchronous reset domains without any soft reset analysis. It reported nearly 40,000 RDC crossings (as shown in table 1).

| Reset domain crossings without soft reset analysis | Severity | Number of crossings | ||

| Reset domain crossing from a reset to a reset | Violation | 28408 | ||

| Reset domain crossing from a reset to non-reset | Violation | 11235 | ||

| Table 1. RDC analysis without soft resets. |

In the second run, we did soft reset analysis and detected 34 soft resets, which resulted in additional violations for RDC paths with transmitter soft reset sources in different clock domains. These were critical violations that were missed in the initial run. Also, some RDC violations were converted to cautions (RDC paths with a transmitter soft reset in the same clock domain) as these paths would be safe from metastability as long as they meet the setup time window (as shown in table 2).

| Reset domain crossings with soft reset analysis | Severity | Number of crossings | ||

| Reset domain crossing from a reset to a reset | Violation | 26957 | ||

| Reset domain crossing from a reset to non-reset | Violation | 10523 | ||

| Reset domain crossing with tx reset source in different clock | Violation | 880 | ||

| Reset domain crossing from a reset to Rx with same clock | Caution | 2412 | ||

| Table 2. RDC analysis with soft resets. |

Authors

Reetika and Sulabh Kumar Khare – Siemens EDA DI SW

Sulabh Kumar Khare is an engineering manager who oversees the development of the CDC product line at Mentor, A Siemens Business. Sulabh has over 13 years of experience in developing EDA software for the design and verification domain. He holds a Masters degree in VLSI design from IIT Kharagpur.