The new process, XSICM03, is now available for early access.

“With its streamlined approach, our process addresses the increasing demand for high-performance SiC devices in automotive, industrial, and energy applications,” says Rico Tillner, CEO of X-FAB Texas, “we enable existing and new customers in creating application-optimised product portfolios through accelerated prototyping and design evaluation, significantly reducing time to market.”

XbloX is X-FAB’s streamlined business process and technology platform designed to accelerate the development of advanced SiC MOSFET technology. It integrates qualified SiC process development blocks and modules for planar MOSFET production, simplifying the onboarding process and significantly reducing design risks and product development time.

By combining proven process modules with robust design rules, control plans, and FMEAs, XbloX enables faster prototyping, easier design evaluation, and shorter time to market.

This approach gives customers a competitive edge, allowing designers to create a diverse product portfolio while achieving production timelines up to nine months faster than traditional development methods.

The platform provides active area design cell size reduction while maintaining robust process controls, as well as leakage and breakdown device performance.

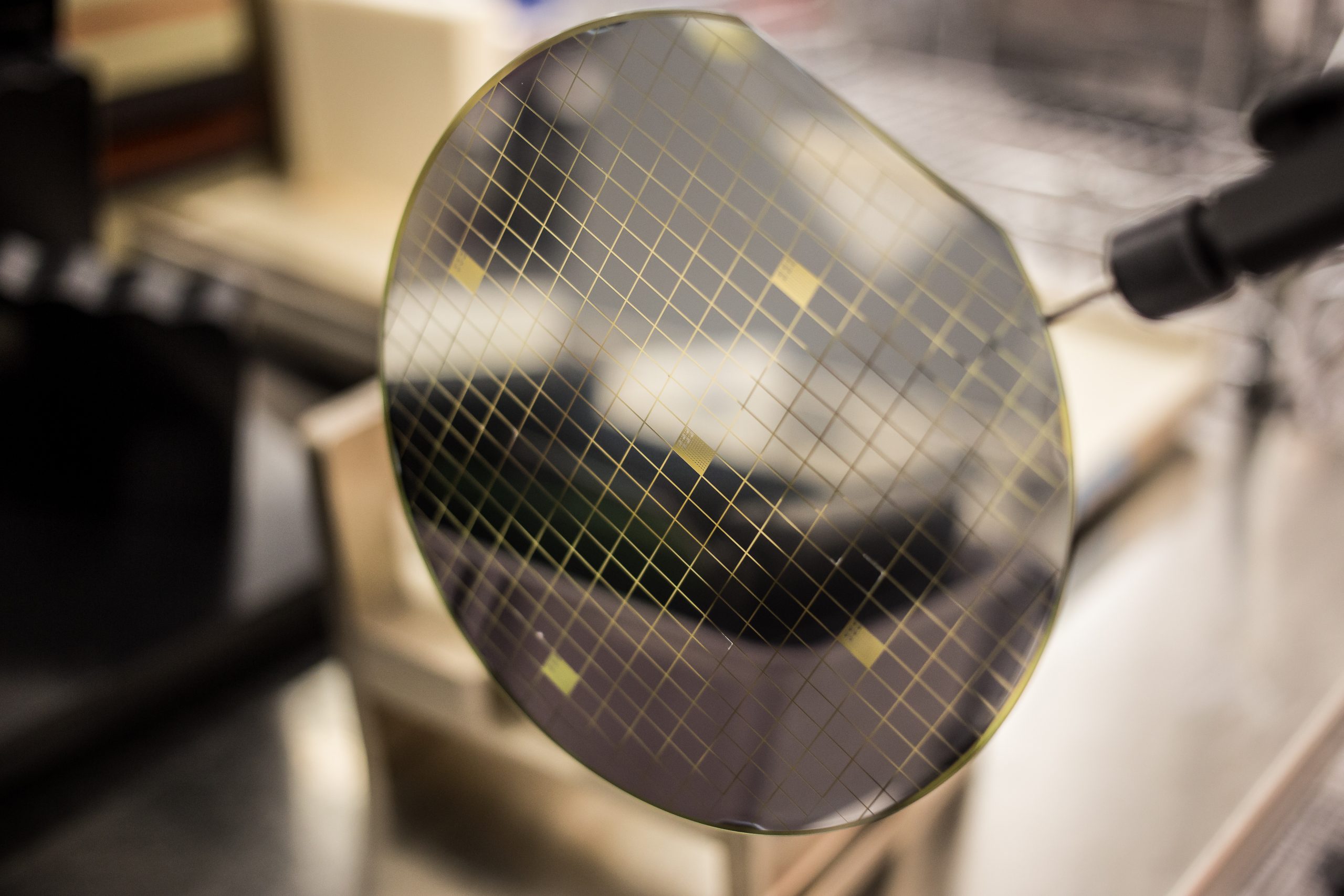

The XSICM03 process with robust design rules allows customers to create SiC planar MOSFETs with a cell pitch that is over 25% smaller than the previous generation. This improvement allows for up to a 30% increase in die per wafer compared to the previous generation.

Leveraging proven process blocks, the platform claims to ensure exceptional gate oxide reliability and device robustness. The enriched PCM library and enhanced design support allow for fast customer tape-out, resulting in faster product development.