It is for ‘matrix’ headlights, that have an array of close-packed power LEDs and projection optics that focus that any pattern on the array forwards from the vehicle – allowing headlights to produce arbitrary beam patterns – usually controlled by an on-board forward facing camera and complex algorithms.

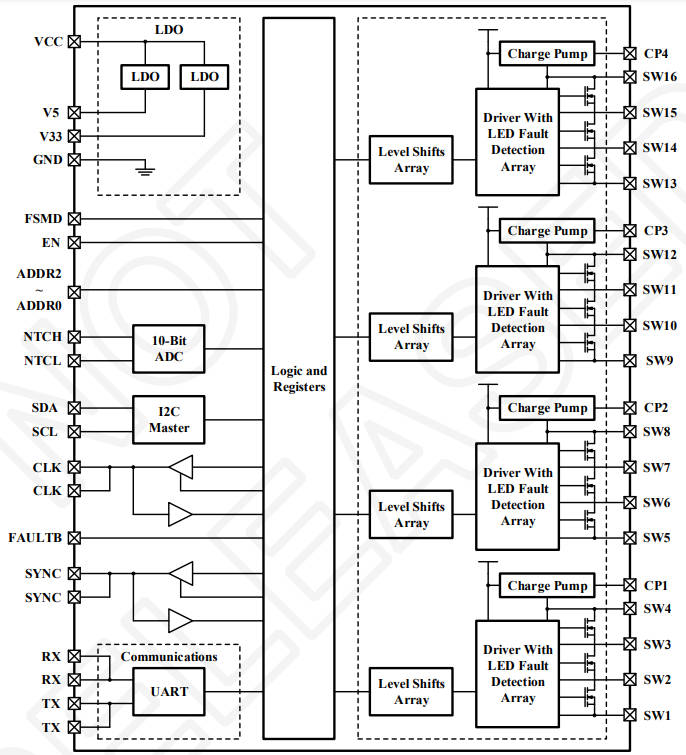

Electrically, this could be driven with row and column drivers, for example, but Lumissil takes a different approach with its device, called IS32LT3365.

For this IC, the LEDs are connected in a long series constant-current string, in which LEDs are left alone to turn them on, or shorted out to turn them off.

Inside are 12 n-channel mosfets connected in four series groups of three (see diagram), and each group of three can operate anywhere in the voltage range 0 to 55V.

The maximum voltage allowable across any individual mosfet is 20V, so it can be connected across several LEDs in the string to control them simultaneously – mosfet on-resistance is ~130mΩ.

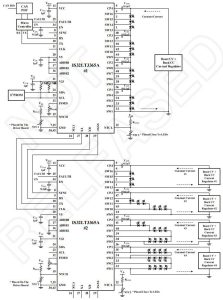

Multiple ICs are envisaged controlling all the LEDs in a matrix, orchestrated by a central computer. There are two control bus options: UART in ‘A’ suffix versions and CAN Lite in B suffix versions.

Multiple ICs are envisaged controlling all the LEDs in a matrix, orchestrated by a central computer. There are two control bus options: UART in ‘A’ suffix versions and CAN Lite in B suffix versions.

“The device supports 30kHz PWM with 10-bit resolution, offering 1,024 unique brightness levels per LED, facilitating the creation of precise beam patterns,” according to the company. “Connectivity ensures synchronisation and control of extensive LED arrays, allowing for coordinated management of potentially hundreds of LEDs.”

Spectrum spreading and slew-rate control is available on the PWM to reduce apparent electromagnetic interference, and the IC is intended for designs complying with ISO 26262 ASIL-B safety standards.

Packaging is 48pad LQFP and operation is over -40 to +150°C.

Find the IS32LT3365 data sheet here – the diagrams above were copied from the Rev.0G issue – the faint wordign is ‘not released’.