The factory-calibrated device measures the absolute pressure and delivers a proportional analogue output signal.

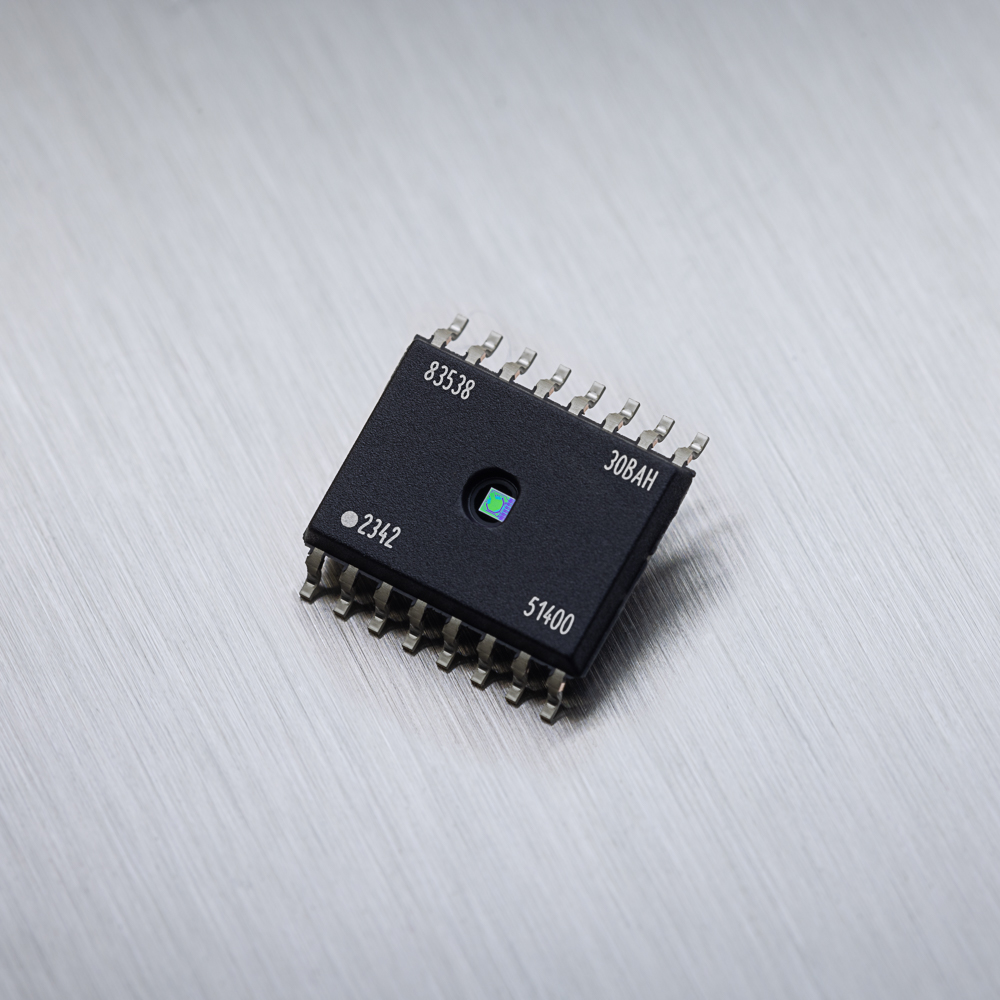

The device – the MLX90830 – makes the module cost-effective by simplifying the system integration into the latest electric vehicles (EVs) thermal management systems.

Triphibian technology allows the sensor to provide measurements considerably above 5 bar while in contact with liquid.

MThis combination of high-pressure sensing while compatible with gas and liquid is achieved by the device’s unique construction.

The sensing mechanism contains a suspended cantilever inside of an SO16 package with the diaphragm at its tip.

The suspended cantilever design of the sensor provides pressure spike immunity up to 2000 bar/msec and static burst level up to 210 bar.

The two available calibrated ranges (10 or 35 bar) are each tailored to fulfill the demands of a distinct EV thermal management system, including low/high-pressure refrigeration loops.

The MLX90830’s design is inherently more robust than rear-side exposed solutions, which still experience a pressure differential between the glass pedestal side and the wire bonding side.

The pressure equalization principle is also valid for frozen media, allowing the MLX90830 to survive in such conditions – claimed to be a first for MEMS pressure sensors.

Compared to existing non-MEMS-based designs, the MLX90830 provides elevated accuracy and robust design, helping to optimize the efficiency of the vehicle’s thermal management systems, allowing for a longer range.

The embedded packaging shrinks the sensor volume against standalone sensor modules.

The MLX90830 includes a sensor readout circuit, digital hardware, voltage regulators, and analog output drivers.

Piezo-resistive elements implanted into the membrane create a Wheatstone bridge to generate an output signal.

This signal is amplified and converted into a digital format, allowing the 16-bit Digital Signal Processing (DSP) to apply temperature compensation before providing the result as an analog output.

The sensor is equipped with advanced protective mechanisms against overvoltage (above +40 V) and reverse voltage (below -40 V). This makes it usable for truck applications.

The MLX90830 has been developed as a Safety Element out of Context (SEooC) under ISO 26262, enabling up to ASIL B system integration ensuring it meets the latest EV safety demands.