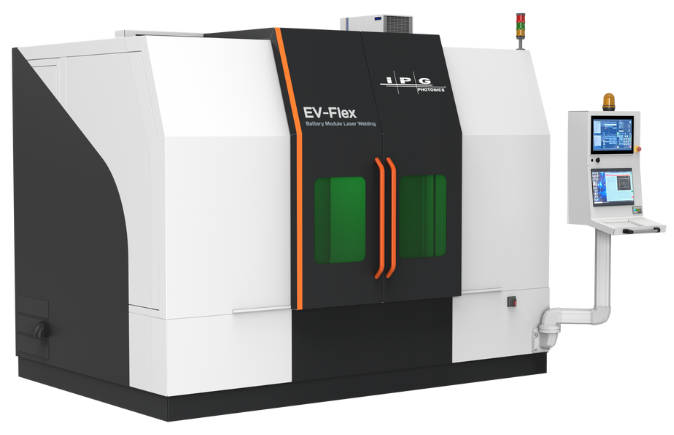

“The EV Flex laser welder uses machine vision and configurable optics to produce micrometer-accurate welds between the terminals on a battery cell and busbar,” according to the company. “Employing optical laser depth detection, the EV Flex accurately controls the area and depth of every weld in large battery packs. Welds have no residue, no spatter, and zero porosity.”

Made by Massachusetts-based IPG Photonics the welder has a 4kW laser and can log data about every laser weld.

“The installation of the world’s first EV Flex machine continues a pattern of capital investment by Alexander Battery Technologies that is making us the most technologically sophisticated manufacturer of embedded battery packs in the world,” claimed Alexander CEO Mark Rutherford. In batteries for automated guided vehicles, automated mobile robots, e-bikes and electric motorcycles, we are achieving quality standards matching those specified by premium electric vehicle manufacturers.”

County Durham-based Alexander Battery Technologies designs and manufactures custom lithium ion and LiFe battery packs, as well as custom battery chargers, and provides related services including supply chain resilience, buffer stock, end-of-life management and rapid prototyping.