This takes three-phase mains into a three-level flying capacitor power factor correction converter (diagram right), which generates a dc bus for two three-phase delta-delta isolated LLC converters that generate ±400Vdc or 800Vdc.

The flying capacitor front-end effectively doubles its switching frequency to reduce input inductor size.

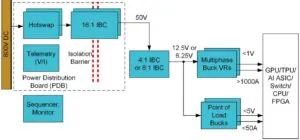

On the receiving end, the company discussed a couple of architectures to convert 800Vdc to 12.5V in racks.

One was similar to Power Integrations concept at the same Summit (although in less detail): A single 64:1 intermediate bus converter dropping 800V to 12.5V in one go.

An extension to this was a single-stage 128:1 converter producing a 6.25V rail for the processor PCBs and an estimated 800V-to-core efficiency peaking at 89% (not including PCB losses).

This lower board voltage allows the on-bord regulator to operate at higher frequency, shrinking this converter to the point where it could dliver power from underneath the processor from the opposite side of the board.

“The challenge with this architecture is that the output current of the 128:1 converter is very large – there would be 2.4 to 3.2kA at 6.25V.,” said TI. “Keeping 6.25V board losses to <1 or 2% will require very large conductors – busbars, for example.”

After the 16:1 isolation stage “the rest of the power architecture would have a similar look and feel as the 48Vdc computing tray – there are several possible variations”, said TI.

TI’s 800V data centre white paper.